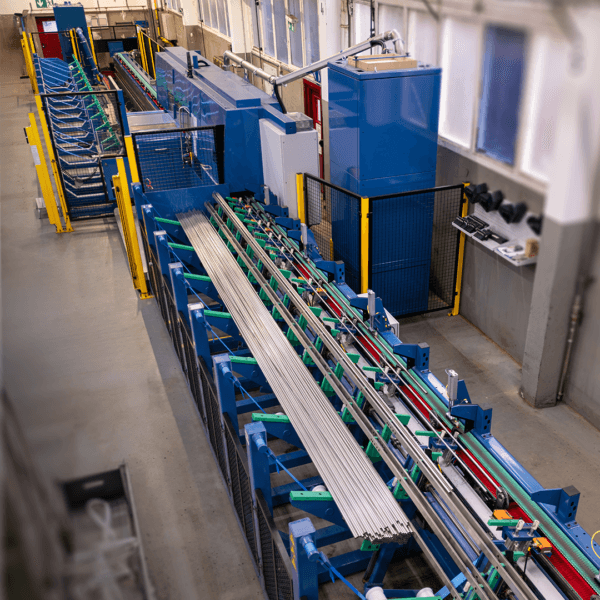

Schoeller stands for progress, accuracy, and innovation – this is once again showcased with the introduction of the new Rattunde cutting system. With this technological investment, Schoeller achieves another milestone in the development of its site and meets the growing demands of the market with state-of-the-art technology.

At Schoeller, site development is not only the key to driving current innovations but also the foundation for sustainable, future-proof production. The new Rattunde cutting system plays a crucial role in this: it replaces the previous cutting machine and enables a new level of accuracy, efficiency, and quality.

What makes the new cutting system so special?

By introducing the new Rattunde cutting system, Schoeller not only solved a previous technical challenge but also strategically paved the way for the future. The new system offers the following advantages:

- Higher performance: Even the most demanding materials are processed with the highest reliability and consistent quality.

- Reduced setup times: Tool-free adjustments and shorter changeover times save valuable time in engineering and production.

- Integrated efficiency: An integrated deburring brush eliminates additional processing steps and ensures significantly leaner workflows.

- Extended durability: Robust saw blades with considerably longer service life reduce operational costs and ensure even greater reliability in continuous operation.

A seamless project rollout

From the quick dismantling of the old system by our maintenance team to the successful commissioning of the new system – the project was a resounding success. With this future-ready solution, we are further enhancing our efficiency and production quality, underscoring once again our commitment to continuous improvement.